Impact resistant gloves

Back-of-hand bones and soft tissues are extremely vulnerable to impact-related hand injuries among a wide range of job sites. As an industry leader in innovative PPE, HexArmor's impact-resistant technology is designed with the optimal durometer and height to dampen blunt forces and redistribute energy away from the impact – delivering some of the best protection on the market.

Understanding ANSI/ISEA 138 and EN 388 impact performance standards

This U.S.-based impact performance standard will help safety professionals make better informed decisions about glove selection - ultimately keeping more people safe on the job.

Impact protection: ANSI/ISEA 138

The ISEA 138 standard establishes the minimum performance. classification, and labeling requirements for gloves that are designed to protect the knuckles and fingers from impacts based on three performance levels.

How the test works:

To score gloves into their appropriate level, impact protection under ISEA 138 requires consistent, regulated tests on each kind of glove on two areas for impact performance: knuckles and fingers/thumb. On both gloves, knuckles are tested four times and fingers/thumb are tested five times.

To start, one pair of gloves is required per test. The gloves are cut in half and the back-of-hand (where the impact protection is located) is placed on an anvil. A striker with a force transferred through the glov back-of-hand is recorded with a force gauge that is connected below the anvil and measured in kiloNewtons (kN).

Scoring:

The average of eight knuckles tests are compared to the average of the ten finger tests. The highest average of the two is the impact testing score.

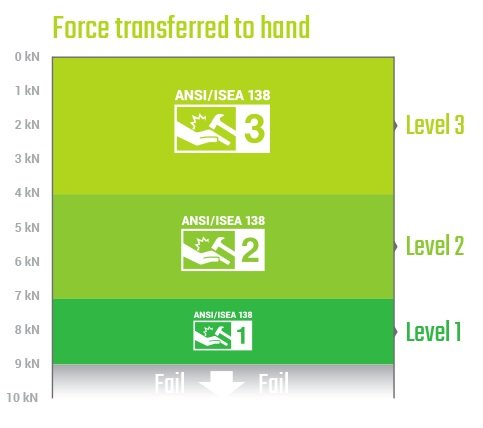

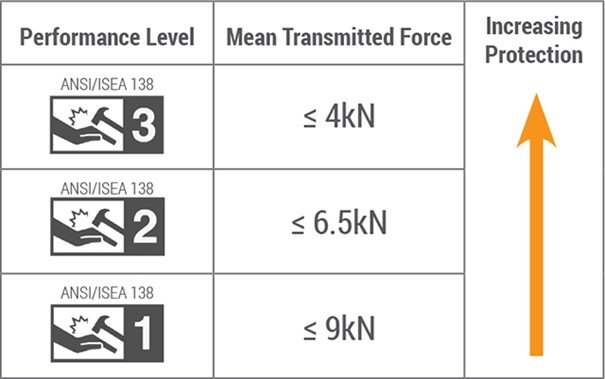

Performance Level 1 - Results in an average peak peak transmitted force of less than or equal to 9 kN. - 55% of force absorbed.

Performance Level 2 - Results in an average peak peak transmitted force of less than or equal to 6.5 kN. - 67.5% of force absorbed.

Performance Level 3 - Results in an average peak peak transmitted force of less than or equal to 4 kN. - 80% of force absorbed.

The chart showcases the ISEA 138 performance levels, with “Performance Level 3” being the highest. Any impact-resistant PPE that scores higher than a 9 kN force transfer will not qualify for a ranking and will fail. With no impact material, the machine registers around 20kN, so in order to pass the test, the impact material must register less than 9kN, reducing the force or energy transferred by 55%. The anvil will drop roughly around 2.5 kilograms from 20 centimetres.

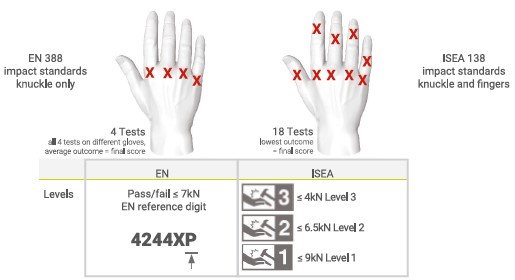

Impact protection: EN 388

The European industrial glove market includes impact testing performance ratings in EN 388, which tests the impact on just the knuckles, and the tests are given a basic score of pass or fail. To pass the test, the transmitted force needs to be less than or equal to 7kN with no single results greater than 9kN.

ANSI/ISEA 138 and EN 388 comparison

The major difference between ISEA 138 and EN388 is that for ISEA 138 the impacts are repeated for both left and right hands of the glove on knuckles and fingers, giving 18 impacts in total, compared to EN388 requirement for 4 impacts on the knuckles only.

The Next Generation of Impact Protection

The most advanced HexArmor™ impact resistance comes with all the dexterity, all the comfort, and more protection than offered by any other impact-protective glove on the market. Our proprietary IR-X™ technology shields our gloves with a full back-of-hand Impact Exoskeleton™ so every joint and knuckle is protected from debilitating blows.

In addition to being 42% taller than competitive impact guards, IR-X™ smash guards are purpose-built to deflect the force of sudden impacts away from the impact point, rather than transferring force directly to the hand. This unique characteristic is what sets IR-X™ safety levels higher than the competition, and its flexibility is what makes the IR-X™ Impact Exoskeleton™ more comfortable and more dexterous than any other impact-resistant technology available.