Cut resistant, needle resistant and pucture resistant safety gloves by HexArmor®

We started this journey more than a decade ago. A group of hardworking people with a new technology that no one had ever seen. One that had the potential to change the cut and puncture safety market. One that could save the lives and livelihood of workers across the world. So we started with one industry. And one glove.

Since 2016 uvex safety group has officially launched the global partnership with Grand Rapids Michigan based protective product manufacturer, HexArmor. HexArmor are the global leaders in extreme cut, impact, puncture and needlestick resistant safety gloves built to tackle a wide variety of hazards and applications. The significant synergies between the two companies create tangible value added for our customers: together, uvex and HexArmor stand for trust, safety and protecting people. No matter the job or the weather, we have the right grips, fabrics, and materials that not only meet but exceed industry standards, ensuring your safety. High-quality products that workers are comfortable wearing lead to greater compliance, resulting in fewer injuries and lower costs.

SuperFabric® : Protecting workers from dangerous cuts, puncture and needle stick hazards.

HexArmor® hand and body PPE is designed to provide extreme cut, puncture and needle resistance in the workplace. Thanks to SuperFabric®, HexArmor®'s exclusively licensed solution, workers are protected from the most dangerous cut and puncture hazards on the job – including blades, wire, metal, and glass – helping to prevent life-changing injuries and saving companies millions in medical expenses. SuperFabric® brand materials provide ISEA/ANSI level A6-A9 cut resistance and exceed CE Level 5 cut resistance. The small guard plate geometry traps and blocks hazards, offering flexibility while preventing punctures from reaching the skin, an injury that could lead to a laceration.

Common cut resistant materials such as synthetic woven materials provide some protection from straight-edged or horizontal sharp hazards, but they can be easily pierced because of the knit properties of the material. SuperFabric® guard plates are engineered to deflect and block hazards by limiting the space between them which in turn prevents cut and puncture hazards from reaching the users hand. The breathable fabric allows air to pass through for long-lasting comfort and unlike most common cut protection material, it will not degrade from UV exposure.

Types of SuperFabric® material

HA607 is the highest cut SuperFabric® material available. It incorporates a single layer construction with cotton material underneath. Cotton substrate gives wearers the best feeling material on their hand while also being the most flexible and soft, allowing employees the highest level of comfort.

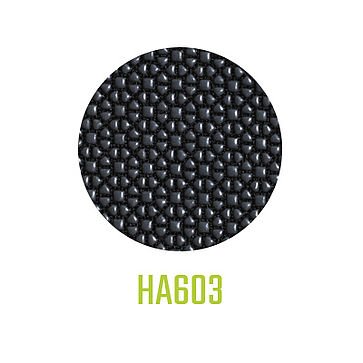

HA603R SuperFabric® brand material offers both high cut and high blunt puncture resistance. Tightly woven polyester provides a strong base for the SuperFabric® guard plates, which gives the material maximum burst strength while also providing high cut resistance.

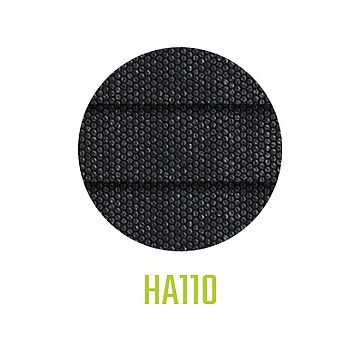

HA110 SuperFabric® brand materials offer exceptional needlestick protection (when layered) and high cut protection. Needlestick protection is only available when layered due to the geometry and offsetting of the guard plates on the material - also providing cut protection ANSI/ISEA level A7 to A9.