Hand Protection from Thermal Hazards

Many industries involve processes where the employee is exposed to thermal risks, such as manufacturing, catering, or foundaries. It is not always possible to remove these hazards so employees will require safety gloves that offer adequate protection to help prevent injuries.

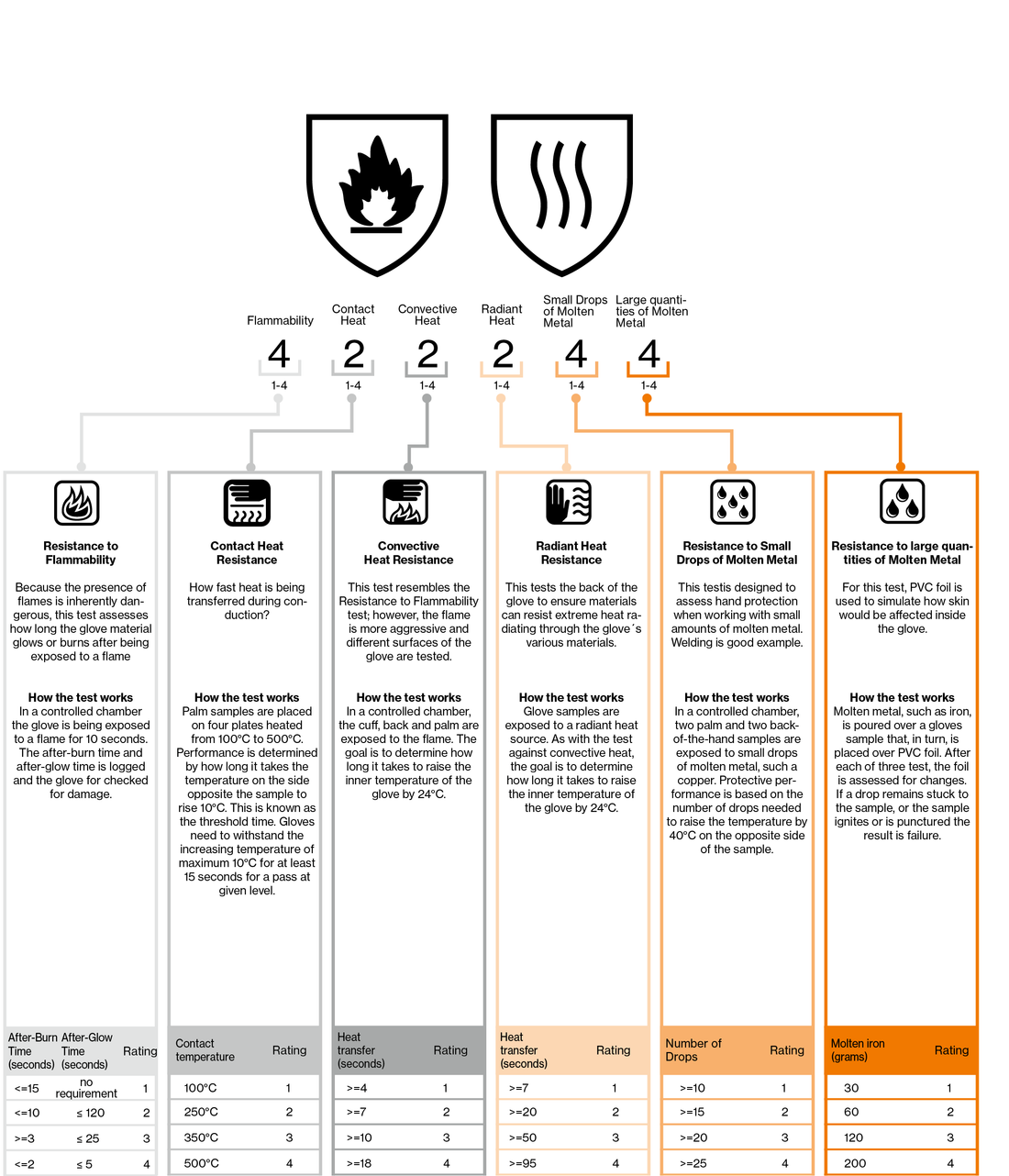

That's why the European standard DIN EN 407 regulates the minimum requirements and specific test methods for safety gloves in relation to thermal risks. Safety gloves certified in accordance with this standard protect the wearer from, for example, contact heat, radiant heat and small splashes from molten metal. EN 407 is made up of six unique glove tests, each graded on a scale of 0 to 4, where the higher the EN 407 score the better.

It's worth remembering, not every job requires gloves with the highest level of thermal protection, so when working with extreme heat, flames, or molten materials, it’s good to know how different gloves stack up. The EN 407 standard is there so you can be confident in your glove selection - as when the heat is on, not all gloves are created equal.

Important changes to EN 407 standard

In the latest version of DIN EN 407, as of 2020, the first performance class is no longer named “resistance to flammability”, but is now called “limited flame spread”. If the glove has not been tested for this, a new pictogram is used (see above right). However, there are no changes to the performance classes. The test described in DIN EN 407 assigns safety gloves a performance class in relation to each of the individual thermal hazards. It is important that the glove does not come into contact with open flames if it does not meet the criteria of performance class 3 in the limited flame spread test.

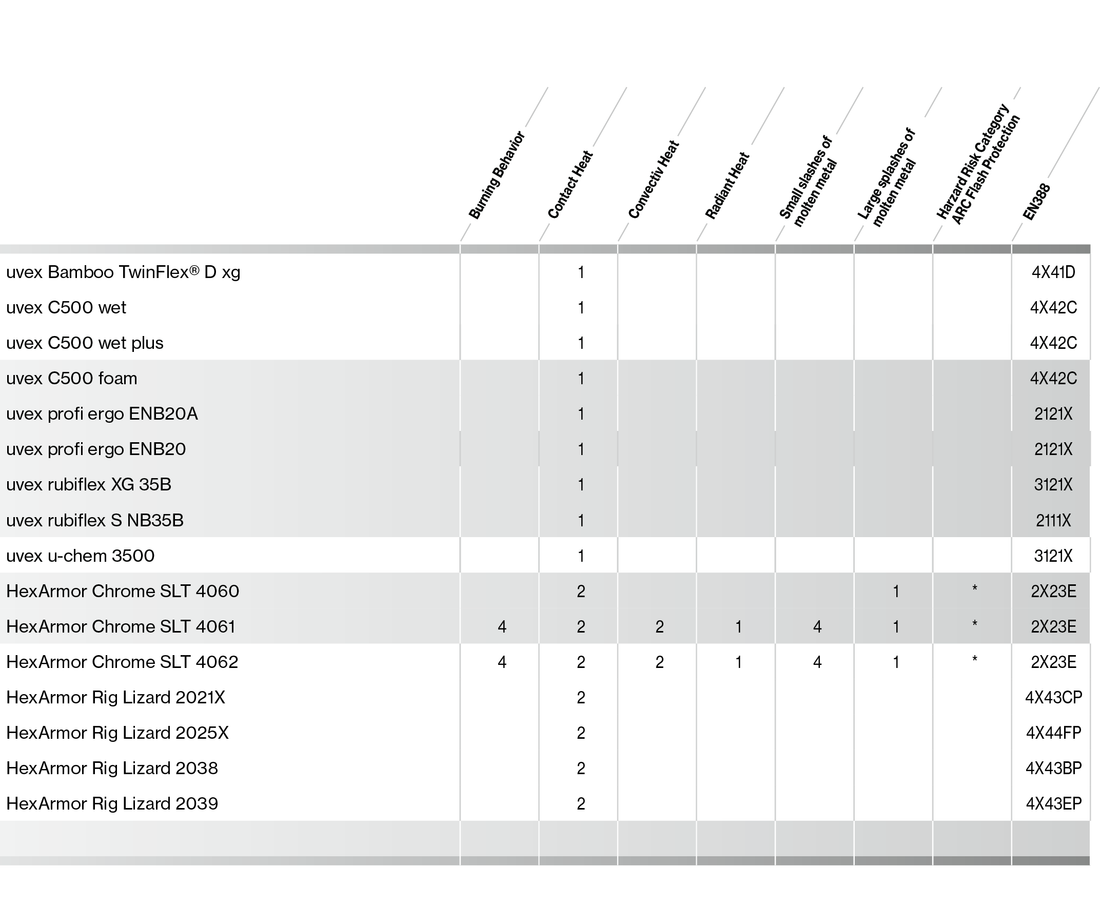

EN 407 rated safety gloves

uvex Bamboo Twinflex D xg

Tactical feel and cut protection perfectly combined

The patented Bamboo TwinFlex® technology combines the best of both worlds in one cut protection glove (Cut Level D). On the inside of the glove, wearers experience noticeable comfort for thanks to the natural bamboo fibres that perfectly adapt to your individual handshape in 3-5 minutes. On the outside of the glove, our high-performance fibres provide reliable high-level protection against external hazards such as abrasion and cutting.

C 500 Glove Series

Cut and heat protection combined

The uvex C500 series sets standards regarding protection, comfort, flexibility, tactility and economy. This high-tech safety glove combines all of these qualities with the highest level of cut protection, level 5/C. The uvex C500 foam is especially suitable for dry or slightly damp working conditions.

Special Protection

Excellent grip on warm and wet workpieces

The uvex u-chem 3500 chemical protection gloves are ideal for handling a variety of different chemicals. Thanks to their full-surface chloroprene and NBR coating, the gloves offer excellent grip and are resistant to acetone, cleaning agents, adhesives and solvents.

Impact protection and grip

A grip for every job

The Rig Lizard® Series is purpose-built to provide maximum grip in tough situations – with over five grip options for water, oils, muds, and lubricants. Each glove is also equipped with our highly flexible IR-X® Impact Exoskeleton™, keeping hands protected from smash and pinch injuries. This combination of multiple technologies and features makes the Rig Lizard® the ideal solution for common oil, gas, and mining hazards. With options for cold weather protection, your hands can stay safe and comfortable in any environment.

Comfort + Cut Protection. Redefined.

Arc flash & contact heat rated safety glove

The HexArmor Chrome SLT® features an extended safety cuff and a goatskin leather palm to give workers the traditional style of comfort they love while providing cut and Arc Flash protection - all while being designed with unsurpassed comfort, dexterity, and protection.